Effective Digitizing for Embroidery: Quick Turnaround

Effective Digitizing for Embroidery: Quick Turnaround

Blog Article

Mastering the Needlework Digitizing Process: Your Ultimate Overview

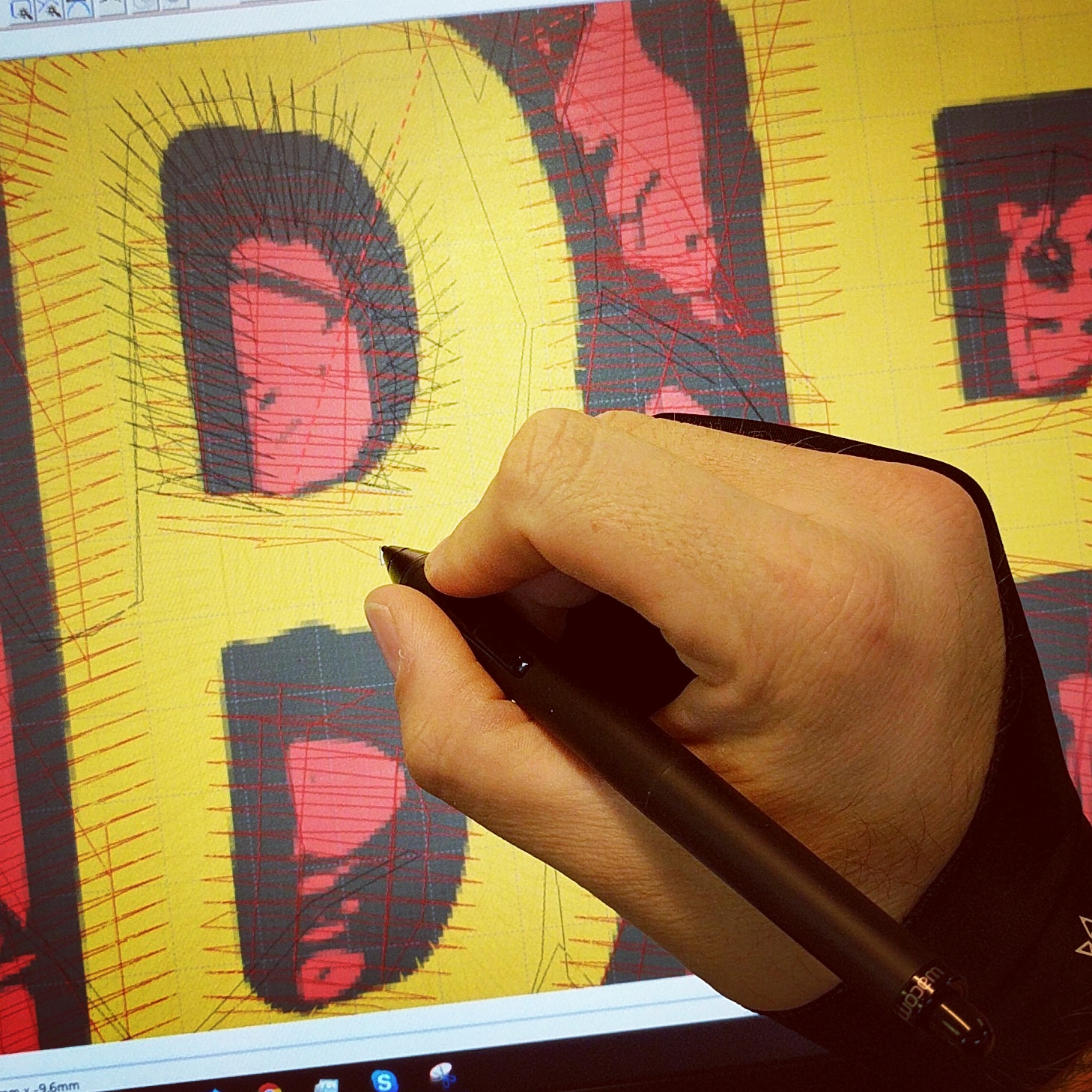

Embroidery digitizing is a meticulous craft that requires accuracy and expertise to translate elaborate designs right into electronic styles for maker embroidery. As craftsmens embark on this trip to grasp the embroidery digitizing procedure, a detailed understanding of the fundamentals establishes the foundation for quality.

Understanding Embroidery Digitizing Fundamentals

Embroidery digitizing fundamentals create the foundation upon which elaborate designs are equated into machine-readable styles for precise stitching. This initial step in the embroidery digitizing procedure is crucial for making sure that the final embroidered product is a loyal representation of the initial style. Recognizing needlework digitizing fundamentals entails realizing vital ideas such as stitch kinds, sew instructions, thickness, underlay, and draw settlement.

Sew types play an important role in determining the visual and textural end result of the stitched style. By choosing the appropriate stitch kind, whether it be satin, fill, or running stitch, digitizers can accomplish the desired result and boost the general quality of the needlework. Furthermore, stitch instructions affects the flow and measurement of the style, while thickness determines the spacing and insurance coverage of the stitches.

Moreover, rug sewing supplies stability to the layout by protecting the fabric and protecting against distortion throughout the embroidery procedure. Pull compensation is an additional necessary consideration to neutralize the natural propensity of material to contract when sewn. Mastering these needlework digitizing basics is essential for creating professional-quality stitched products.

Picking the Right Digitizing Software Application

Choosing the ideal digitizing software is a critical decision that substantially influences the effectiveness and top quality of the needlework digitizing process. Digitizing for Embroidery. When selecting the appropriate digitizing software program, it is necessary to consider factors such as the intricacy of styles you prepare to produce, the user-friendliness of the software program, the level of customer assistance offered, and the compatibility with your needlework machine

There are numerous digitizing software program options readily available in the market, ranging from fundamental programs for beginners to sophisticated software application for specialist digitizers. Some popular selections include Wilcom EmbroideryStudio, Hatch Embroidery Software, and PulseID. These software program plans offer a wide variety of devices and attributes to aid you develop intricate designs effortlessly.

Before deciding, it is suggested to discover the different software program choices via complimentary trials or demonstrations to determine which one best suits your demands. Furthermore, reviewing testimonials and seeking referrals from experienced digitizers can provide useful insights right into the staminas and weak points of each software application bundle (Digitizing for Embroidery). By very carefully assessing your requirements and contrasting the functions of different digitizing software program, you can make an educated choice that boosts your embroidery digitizing workflow

Digitizing Devices and Techniques

Optimizing Layout Setup for Needlework

Understanding the details of design settings is basic in achieving optimum outcomes in the needlework digitizing procedure, building upon the foundation laid by comprehending digitizing devices and techniques. When maximizing layout setups for embroidery, it is necessary to think about variables such as stitch type, thickness, rug, draw compensation, and registration. Sew kind option affects the general appearance and feel of the layout, with options like satin, fill, and running stitches supplying different textures and impacts. Thickness describes the spacing and density of stitches, influencing the design's insurance coverage and longevity. Correct padding sewing supplies security and avoids textile distortion, especially for complex designs or on stretchy materials. Draw compensation changes for textile stretch during sewing, guaranteeing accurate style duplication. Enrollment settings straighten different aspects of the style properly, preserving general layout integrity. By fine-tuning these layout setups, embroiderers can boost the top quality and accuracy of their embroidered creations.

Troubleshooting Common Digitizing Issues

When running into common digitizing concerns during the embroidery procedure, it is vital to recognize the origin and implement efficient solutions without delay. One common issue is stitch thickness issues, where stitches may be as well thick, causing the material to pucker, or also sparse, causing spaces in the design. Readjusting the stitch density settings in web the digitizing software application can help resolve this concern.

An additional regular challenge is thread breaks throughout the embroidery procedure. This can occur as a result of numerous reasons such as wrong tension setups, boring needles, or using low-grade string. Making sure appropriate maintenance of the embroidery equipment, consisting of normal needle changes and stress modifications, can lessen the occurrence of thread breaks.

Furthermore, layout registration errors can cause misaligned components within the needlework layout. Examining the layout placement in the digitizing software application and making needed modifications prior to stitching can aid in avoiding this issue. By resolving these usual digitizing problems immediately and properly, you can ensure a smoother needlework procedure and premium ended up products.

Final Thought

Finally, grasping the embroidery digitizing procedure calls for a strong understanding of the fundamentals, the right selection of software, and knowledge of tools and strategies. Maximizing have a peek at this site design settings and fixing common digitizing concerns are crucial actions in guaranteeing top notch embroidery results. By adhering to these steps faithfully, one can achieve accuracy and efficiency in the digitizing process.

Report this page